Shenzhen Manufacturer Best Industrial Metal Precision Racing Motorcycle Auto Car Spare Parts Custom Titanium/Stainless Steel/Brass/Aluminum CNC Engine Parts

Overview Shenzhen Manufacturer Best Industrial Metal Precision Racing Motorcycle Auto Car Spare Parts Custom Titanium/St

Send your inquiryDESCRIPTION

OverviewBasic Info.

| Model NO. | engine parts |

| Material | Metal, Metal |

| Application | Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Spinning Machinery, Metal Processing Machinery Parts, Metal forging Machinery, Metal Engraving Machinery, Metal Drawing Machinery, Metal Coating Machinery, Metal Casting Machinery, as Requested in Your Drawings, Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Spinning Machinery, Metal Processing Machinery Parts, Metal Forging Machinery, Metal Engraving Machinery, Metal Drawing Machinery, Metal Coating Machinery, Metal Casting Machinery, CE, RoHS, GS, ISO9001 |

| Quality Inspection Tools | Two Dimensional Measuring Instrument/Gauges |

| Surface Finish Provided | Anodizing/Sandblasting/Brush/Polish/Plating |

| More Inspection Tools | Nside and Outside Micrometer / Caliper, etc. |

| Sample Production | Offered Before Mass Production |

| Quality Control Team | Engineers/Ipqc/IQC/Pqc/Fqc and QC Equipments |

| Workable 3D Drawing Format | Step/Igs/X_T/Stl/Solidworks etc |

| Shipping Ways | DHL/UPS/FedEx/TNT or Your Shipping Account |

| Mass Production Time | Usually 15~20 Work Days |

| Factory Visit | Welcome to Pay a Visit! |

| Machining Time Shift | Day & Night Two Shifts to Speed up The Production |

| Production Plan | Provided Once The Order′s Settled Down |

| Sample Production Time | Usually 5~10 Work Days |

| More Finish Provided | Coating/Heat Treatment/Tumbling/Mirror Polish etc. |

| Surface Treatment | Anodizing |

| After-Sales Service | Email Us Anytime If Any Problems |

| Machining Method | CNC Machining |

| Type | Metal Fabrication |

| Production Type | Batch Production |

| Transport Package | Bubble/Plastic Bags or Custom Package |

| Specification | Custom by your 3D/2D drawings |

| Trademark | CNC Machining |

| Origin | Shenzhen, Cn |

| HS Code | 7604299000 |

| Production Capacity | 500000 PCS / Year |

Product Description

Shenzhen Manufacturer Best Industrial Metal Precision Racing Motorcycle Auto Car Spare Parts Custom Titanium/Stainless Steel/Brass/Aluminum CNC engine parts*How to receive an online quotation? Click here or1. Please send us your 3D drawing/2D drawing for us to check all dimension

2. Specify the required material, surface finish, quantity information in the email, we will handle it for you once receiving it soon!Note: Workable 3D Drawing Formats: STEP/IGS/X_T/STL/SOLIDWORKS etc, 2D Drawing with PDF will do.

Our Focus

| Advantages | »Reliable CNC service»Good machining quality»Reasonable Pricing provided»Competitive shipping cost service»MOQ 1PCS and small quantity order accepted»Professional engineering service when any modification required»Any turnkey assembly or customized package requirements, we'll meet your demands! | |||||

| Equipment | »20 sets of CNC turning machines; »30 sets of the most technologically advanced machining CNC milling machines; »25 sets of Multi-Spindle Japan Precision Swiss CNC lathes | |||||

| RFQ | Customer Inquiry →Engineering Communication →Cost Analysis →Sales Analysis →Quote to Customer» 1-3 Work Days Only» Submit RFQ with complete commercial terms | |||||

| Sample Making | Sample Order → Engineering Review → Sample Plan to Customer → Sample Status Tracking → Submit Samples with Doc.» Tooling L/T: 2-4 weeks, Sample L/T: 1 week» Continuous Sample Status Tracking» Complete Documents for sample approval | |||||

| Order Management | CRM System → Open Order Confirm → Logistic Arrangement.» Production L/T: 2-4 wks» Weekly Open Order Confirm» Preferred 3PL Service to Customers | |||||

| Quality Control | Certificates: RoHS, ISO9001:2008, SGS.IQC → IPQC → OQC/FQC → Quality Complain Feedback → Audit & Training.» Plant Audit and Qualified by world famous company» Strict Quality Management Procedure with Traceability | |||||

| Application | »Aerospace»Marine»Motorbike»Automotive»PhotoGear»EDC Tools» lighting fittings»Office equipment»Home appliance»Medical equipment»Telecommunication»Electrical & Electronics»Fire detection system, etc. | |||||

Examples projects

Production information

1). Material Capabilities: Following GB, DIN, and ISO and applying good quality homemade and import materials, we have already provided single/assembly products for international customers mainly from the USA and Europe, etc.

| Stainless Steel | SS201, SS301, SS303, SS304, SS316, SS416 etc. |

| Steel | Mild steel, Carbon steel, 4140, 4340, Q235, Q345B, 20#, 45#, etc. |

| Brass | HPb63, HPb62, HPb61, HPb59, H59, H62, H68, H80 etc. |

| Copper | C11000, C12000, C12000 C36000 etc. |

| Aluminum | AL6061, Al6063, AL6082, AL7075, AL5052, A380 etc. |

| Iron | A36, 45#, 1213, 12L14, 1215 etc. |

| Plastic | ABS, PC, PE, POM, Delrin, Nylon, PP, PEI, Peek etc. |

2). Quality control: *We have specialized QC testers to check the quality of the products according to different customers' requirements. Usually, it's a random inspection, and we also offer 100% inspection at a reasonable price if required.*We have IQC to check the dimensions and surface of the incoming material*We have PQC to inspect full-course during the manufacturing processing*We have FQC to inspect all the anodizing/plating and other finishes' products from our supplier and proceed with the professional quality and appearance inspection before shipping. 3).Surface Finish: sandblasted/normal and hard anodized finish/polish/coating/polish/passivation/plating/brush/heat treatment/fine glass beads/grounding/tumbled finish , etc. More detailed information for different material parts is below,

Aluminum parts | BrushingPolishingClear AnodizedColor AnodizedSandblast AnodizedChemical Film |

| Stainless Steel parts | PolishingPassivatedSandblastingPlating |

| Steel Parts | Zinc platingOxide BlackNickel platingChrome platingCarburizedHeat treatmentPowder Coated |

| Plastic Parts | Chrome platingPolishing |

4). Payment terms: T/T payment. The Sample order is paid by full payment; Mass production with order amount exceeding can be paid a 50% deposit before production, and balance paid before shipping.5). Production schedule: Usually, it takes 5~10 working days for sample production; 15~20 working days for mass production days, it depends on your design, simple parts can be produced quickly, the complicated design parts would take us more machining time.6). Machining capability: 30 sets of the most technologically advanced machining CNC milling machines, 20 sets of CNC turning machines, 25 sets of Multi-Spindle Japan Precision Swiss CNC lathes, and 4 sets of 2D &3D CMM (image measuring instrument) quality control equipment 3 QC staff, enabling CNC Manufacturing to deliver precise parts within the tightest of tolerances, ensuring the highest quality results to meet differentcustomers' requirements.7). Tolerance: +/- 0.02mm (for Metal shaft), +/-0.03mm ( for plastic), for special tolerance requirements, please point them out in the email, we will Check if it's feasible to make it after studying it.8). Packing & Shipping way:

About us

CNC Manufacturing is an industry-leading expert in the precision machining of performance-critical parts in diverse industries, including electronics products, audio parts, photographic equipment, Medical devices, and the automotive & racing industry, etc.

About 150~200 employees, Zoe CNC machining Co., Ltd. Runs 30 sets of the most technologically advanced machining CNC milling machines, 20 sets of CNC turning machines, 25 sets of Multi-Spindle Japan Precision Swiss CNC lathes, and 4 sets of 2D &3D CMM (image measuring instrument) quality control equipment 3 QC staff, enabling CNC Manufacturing to deliver precise parts within the tightest of tolerances, ensuring the highest quality results to meet different customers' requirements.We put high attention and effort into all of the work that we do. Every part that comes off our machines is an extension of us. We take great pride in bringing machining excellence to our customers. The amazing quality parts we machined here will be your best choice to find a supplier!

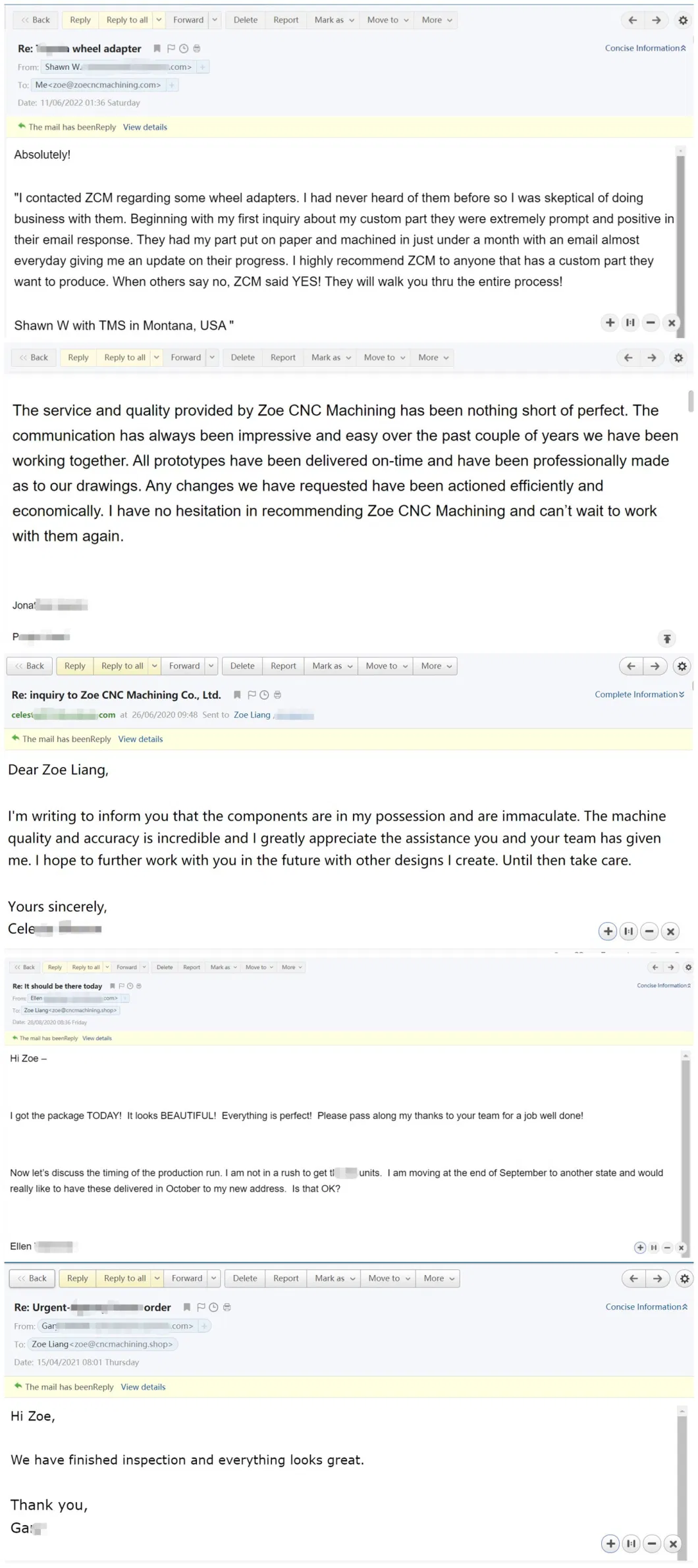

Customer's comment

Remark: The products and pictures shown above are only to present the scope of our manufacturing types. We're happy to evaluate if we could custom the parts according to your drawings or samples after receiving them.

Send us an email now if any inquiries!