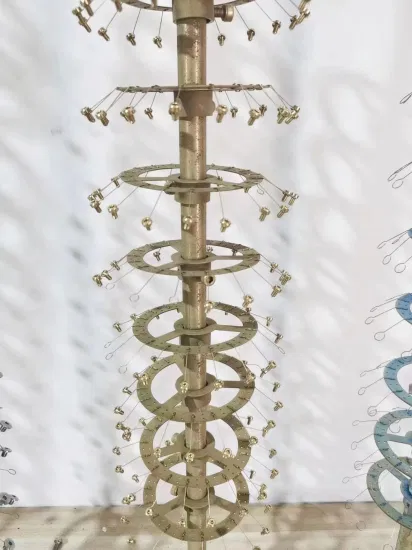

Blue 0cr23al5 Containing Titanium Spiral Wire for Electric Heating Circle

0cr23al5 Containing Titanium Fecral High Quality Spiral Heating Resistance Wire General Description FeCrAl alloy is made

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | 0cr23al5 Fecral Heating Resistance Wire |

| Diameier | 0.01-10mm |

| The Highest Use Temperature | 1300c |

| Resisivity | 1.35 |

| Density | 7.25g/cm3 |

| Characteristics | High Resistivity, Good Oxidation Resistance |

| Color | Blue |

| Transport Package | Wooden Cases or Cartons |

| Specification | 23%Cr |

| Trademark | HUONA |

| Origin | Shanghai |

| HS Code | 7408220000 |

| Production Capacity | 300ton/Month |

Product Description

0cr23al5 Containing Titanium Fecral High Quality Spiral Heating Resistance Wire

General Description

FeCrAl alloy is made by a high-temperature, ferritic iron-chromium-aluminium alloy which can be used at temperatures up to 1350degrees. Typical applications for FeCrAl are as electrical heating elements in high-temperature furnaces in the heat treating, ceramics, glass, steel, and electronics industries.

Feature

With long service life.Heating up fast.High thermal efficiency.Temperature uniformity. Can use vertically. When being used in the rated voltage,there is no volatile matter.It is an environmental protection electric heating wire. And an alternative to the costly nichrome wire.Can be customized according to customer requirements

FeCrAl alloys are characterized by excellent oxidation resistance and very good form stability resulting in long element life.

They are typically used in electrical heating elements in industrial furnaces and home appliances.

Fe-Cr-Al alloy with high resistivity and serviceability temperature than that for NiCr alloy and also has lower price.

Applications

Iron-chrome-aluminium electric resistor strip is widely used for making electric heating elements in home appliances and industrial furnaces. Typical applications are flat irons, ironing machines, water heaters, plastic moulding dies, soldering irons, metal sheathed tubular elements and cartridge elements

application area

Our products are widely used in heat treatment equipment, auto parts, iron and steel manufacturing,aluminum industry, metallurgical equipment, petrochemical equipment, glass machinery, ceramic machinery,food machinery, pharmaceutical machinery, and power engineering industry.

Chemical Content, %

| Alloy material | Chemical composition % | |||||||||

| C | P | S | Mn | Si | Cr | Ni | Al | Fe | others | |

| max(≤) | ||||||||||

| 1Cr13Al4 | 0.12 | 0.025 | 0.025 | 0.7 | ≤1.00 | 12.5-15.0 | - | 3.5-4.5 | Rest | - |

| 0Cr15Al5 | 0.12 | 0.025 | 0.025 | 0.7 | ≤1.00 | 14.5-15.5 | - | 4.5-5.3 | Rest | - |

| 0Cr25Al5 | 0.06 | 0.025 | 0.025 | 0.7 | ≤0.60 | 23.0-26.0 | ≤0.60 | 4.5-6.5 | Rest | - |

| 0Cr23Al5 | 0.06 | 0.025 | 0.025 | 0.7 | ≤0.60 | 20.5-23.5 | ≤0.60 | 4.2-5.3 | Rest | - |

| 0Cr21Al6 | 0.06 | 0.025 | 0.025 | 0.7 | ≤1.00 | 19.0-22.0 | ≤0.60 | 5.0-7.0 | Rest | - |

| 0Cr19Al3 | 0.06 | 0.025 | 0.025 | 0.7 | ≤1.00 | 18.0-21.0 | ≤0.60 | 3.0-4.2 | Rest | - |

| 0Cr21Al6Nb | 0.05 | 0.025 | 0.025 | 0.7 | ≤0.60 | 21.0-23.0 | ≤0.60 | 5.0-7.0 | Rest | Nb add0.5 |

| 0Cr27Al7Mo2 | 0.05 | 0.025 | 0.025 | 0.2 | ≤0.40 | 26.5-27.8 | ≤0.60 | 6.0-7.0 | Rest | |

Main technical characteristics of FeCrAl Alloy:

Brand Property | 1Cr13Al4 | 1Cr21Al4 | 0Cr21Al6 | 0Cr23Al5 | 0Cr25Al5 | 0Cr21Al6Nb | 0Cr27Al7Mo2 | |

| Major chemical component% | Cr | 12.0-12.5 | 17.0-21.0 | 19.0-22.0 | 20.5-23.5 | 23.0-26.0 | 21.0-23.0 | 26.5-27.8 |

| Al | 4.0-6.0 | 2.0-4.0 | 5.0-7.0 | 4.2-5.3 | 4.5-6.5 | 5.0-7.0 | 6.0-7.0 | |

| Fe | Balance | Balance | Balance | Balance | Balance | Balance | Balance | |

| Re | Appropriate | Appropriate | Appropriate | Appropriate | Appropriate | Appropriate | Appropriate | |

| Addition Nb:0.5 | Addition Mo:1.8-2.2 | |||||||

| Component max. use temperature | 950 | 1100 | 1250 | 1250 | 1250 | 1350 | 1400 | |

| Melting Point | 1450 | 1500 | 1500 | 1500 | 1500 | 1510 | 1510 | |

| Density g/cm3 | 7.40 | 7.35 | 7.16 | 7.25 | 7.10 | 7.10 | 7.10 | |

| Resistivity μΩ·m,20 | 1.25±0.08 | 1.23±0.06 | 1.42±0.07 | 1.35±0.06 | 1.45±0.07 | 1.45±0.07 | 1.53±0.07 | |

| Tensile Strength Mpa | 588-735 | 637-784 | 637-784 | 637-784 | 637-784 | 637-784 | 684-784 | |

| Extension rate% | 16 | 12 | 12 | 12 | 12 | 10 | ||

| Repeated bending frequency | 5 | 5 | 5 | 5 | 5 | |||

| Fast lift h/ | - | 80/1300 | 80/1300 | 50/1350 | ||||

| Specific Heat J/g. | 0.490 | 0.490 | 0.520 | 0.460 | 0.494 | 0.494 | 0.494 | |

| Heat Conduction Coefficient KJ/M.h | 52.7 | 46.9 | 63.2 | 60.1 | 46.1 | 46.1 | 45.2 | |

Linear expansion coefficient aX10-6/ (20-1000) | 15.4 | 13.5 | 14.7 | 15.0 | 16.0 | 16.0 | 16.0 | |

| Hardness HB | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | |

| Microstructure | Ferritic | Ferritic | Ferritic | Ferritic | Ferritic | Ferritic | Ferritic | |

| Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | |

If you have any questionsPls click below "send" button to contant us and get the best price

Related Products